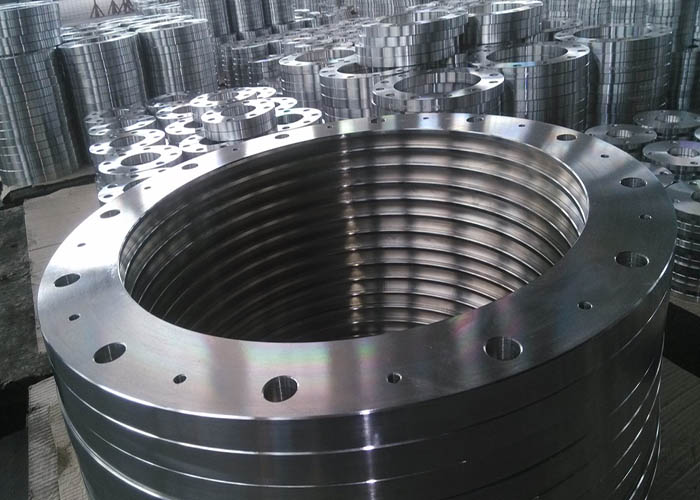

Legering staal flens

Spesifikasie:

| Graad | ASTM / ASMEA182F1 / F51 F9 / F111 F221 F91 |

| Standaard | ANSI-flense, ASME-flense, API, MSSP, BS-flense, DIN-flense, EN-flense, NACE ens |

| Grootte | 1/2 "tot 36" |

| Tik | Lasnekflense (WNRF), Slip-on-flense (SORF), Blinde flense (BLRF), Rondvoegflense (SOLJ), Sok- sweis |

| Flense (SWRF), geskroefde (geskroefde) flense, lang sweisflense (LWNRF), brilblinde flense | |

| Afstands- en blinde flense, ringtipe gewrigsflense (RTJ), vermindering van flense, verhoogde gesig (RF) flense, openingflense | |

| Groot deursnee flense, pasgemaakte flense, tekenflense, gesmee flense, plaatflense, plat gesig Flense, ens | |

| Afmetings | ANSI / ASME B16.5, B 1647 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, ens |

| Klas / druk | 150#, 300#, 600#, 900#, 1500#, 2500# |

| PN6, PN10, PN16, PN25, PN40, PN64 ens |

ASME SA 182 AS Pipe Flange Equivalent Material

| Material Group | Common Name | Tik | UNS | Forging Spec. | Casting Spec. Equivalent | DIN | DIN W. No | Toepassing |

|---|---|---|---|---|---|---|---|---|

| Low AS | Moly Steel | C-1/2Mo | K12822 | A182-F1 cl2 | A217-WC1 | 15M03 | 1.5415 | Up to 470ºC* (875ºF) |

| AS Chrome Moly | 1.1/4Cr-1/2Mo | K11572 | A182-F11 cl2 | A217-WC6 | 13CRM044 | 1.7335 | Up to 593ºC (1100ºF) | |

| 2.1/4Cr-1Mo | K21590 | A182-F22 cl3 | A217-WC9 | 10CRM0910 | 1.7380 | Up to 593ºC (1100ºF), HP steam | ||

| 5Cr-1/2Mo | K41545 | A182-F5/F5a | A217-C5 | 12CRMO195 | 1.7362 | High temp refinery service | ||

| 9Cr-1Mo | K90941 | A182-F9 | A217-C12 | X 12 CrMo 9 1 | 1.7386 | High temp erosive refinery service | ||

| 9Cr-1Mo-V | A182-F91 | A217-C12A | X 10 CrMoVNb 9 1 | 1.4903 | High pressure steam |

Chemical Element of Alloy Steel Flange Material

| Graad | C | Mn | Si | P | S | Cr | Mo |

|---|---|---|---|---|---|---|---|

| F1 | 0,15 maks | 0.3-0.6 | 0.5 | 0.03 | 0.03 | 4-6 | 0.44-0.65 |

| F5 | 0,15 maks | 0.3-0.6 | 0.5-1.0 | 0.03 | 0.03 | 4-6 | 0.44-0.65 |

| F9 | 0,15 maks | 0.3-0.6 | 0.5-1.0 | 0.03 | 0.03 | 8-10 | 0.9-1.1 |

| F11 | 0.5-0.15 | 0.3-0.6 | 0.5-1.0 | 0.03 | 0.03 | 1.0-1.5 | 0.44-0.65 |

| F12 | 0,15 maks | 0.3-0.6 | 0.5 | 0.03 | 0.03 | 4-6 | 0.44-0.65 |

| F22 | 0.50.15 max | 0.3-0.6 | 0.5 | 0.03 | 0.03 | 4-6 | 0.44-0.65 |

| F91 | 0,15 maks | 0.3-0.6 | 0.5-1.0 | 0.03 | 0.03 | 8-10 | 0.9-1.1 |

Mechanical Properties of ANSI B16.5 Alloy Steel Slip On Flange

| Graad | Trek sterkte | Opbrengssterkte (0,2% verrekening) | Verlenging |

|---|---|---|---|

| F1 | 275 | 485 | 20 % |

| F5 | 275 | 485 | 20 % |

| F9 | 380 | 585 | 20 % |

| F11 | 205 | 415 | 20 % |

| F12 | 275 | 485 | 20 % |

| F22 | 205 | 415 | 20 % |

| F91 | 380 | 585 | 20 % |

Specification Chart of Alloy Steel Weld Neck Flange

| ASTM spesifikasie | ASTM A182 , ASME SA182 |

|---|---|

| Size in inch | 1/2 inch (15 NB) to 48 inch (1200NB) |

| Standaarde | ANSI/ASME B16.5, B16.48, B 16.47 Series A & B, EN-1092, BS4504, BS 10, DIN |

| Class and Pressure Chart | 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc. |

ASME SA182 AS openingflense,

ANSI B16.5 Legeringsplaatflense,

Legeringstaal A182 pypflens,

Legering A182 Rondvoegflense,

Legering staal blinde flens

Legeringstaalflense

Chrome Moly-plaatflens

A182 legering staal sweis nek flens,

Skroefdraad-flens van legering